This fall, we once again competed in the annual pumpkin chunkin event hosted by CAMP. This year, due to COVID-19, the usual large event was canceled. However, members of our team worked hard to hold a smaller version of the event on campus. Typically, the event is held in Memorial Park, but this year it was held at the practice field behind the King Center on campus and live-streamed on the school Facebook page.

Once we knew the competition was going to take place, we began work on making improvements to the trebuchet. It was already one of the more powerful ones at the competition last year but struggled with accuracy. Also, due to the multiple degrees of motion, there was a bit of instability in the design. Additionally, the primary frame of the trebuchet was getting a bit old and some of the beams needed to be replaced.

To solve these issues, the team decided to completely disassemble the trebuchet and reassemble it from the ground up. The frame design was kept largely the same, but with refined design in a few of the week points and reinforced uprights. The arm was also completely redesigned to be stronger and more efficiently built with steel reinforcement in high stress locations and material removed where it wasn’t as beneficial.

The lift and release mechanisms were also completely redesigned with rigging running up the uprights through pulleys to raise the weights directly. This allows the trebuchet to lift more weight with lower resulting forces on the frame and arm. Also, the hand winch was replaced with an electric winch to increase safety and make it easier to lift heavier loads (also, our team seems to be mildly obsessed with adding motors to everything). The initial plan was to disengage the winch to throw the projectile. But after testing, we learned that the winch does not fully disengage resulting in a large amount of energy lost due to friction. To solve this, the team created two release mechanisms that attach to the two sides of the weights from the winch cable. When a trigger rope is pulled, both mechanisms release simultaneously.

These changes worked quite well, and the trebuchet was performing mostly as intended. Unfortunately, (as per usual) our team didn’t leave enough time for testing and as such were performing test throws the morning of the competition. We decided to attempt a high weight throw to get a sense for the max distance we could throw. Unfortunately, this revealed a weak point in the design in a rather dramatic fashion as the sling connection at the tip of the arm failed and the projectile launched straight up in the air and crashed back down several seconds later. The energy of the throw had cracked the tip of the arm in half and damaged the tang. The team quickly repaired the tip of the arm (in a somewhat makeshift fashion) and loaded up the trebuchet to move it.

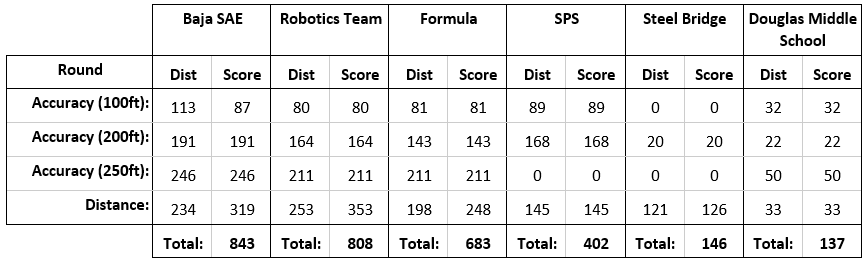

At the competition, surprisingly the arm held together without issue. We didn’t attempt another max weight throw, but were still able to get the longest throw at the competition with a distance of 253ft. Sadly, we didn’t fair quite as well in the accuracy throws due to our limited number of test throws. It was still a great showing however, and we had a great time. The full list of results for all of the teams are shown below.

Baja took home the first place honors with very precise accuracy throws and the second longest throw with a distance of 234 ft. Congratulations to them as well as all teams that competed! Also, huge thanks to everyone who worked hard to make the competition happen this year. We are looking forward to chucking some more pumpkins next year!